-

Knives For Sale

I use PayPal for my online transactions. Shipping anywhere in the US is included in the purchase price, a small fee may be charged for air mail or for outside the USA. -

Fenris Forge Blades & Blacksmithing

I believe that forge & anvil is the best way to fashion a lasting blade. I prefer to make Pattern welded blades, also called Damascus, with metals capable of making very good blades by themselves, not just choosing steels by looks. -

What is in our Forge Blades & Blacksmithing

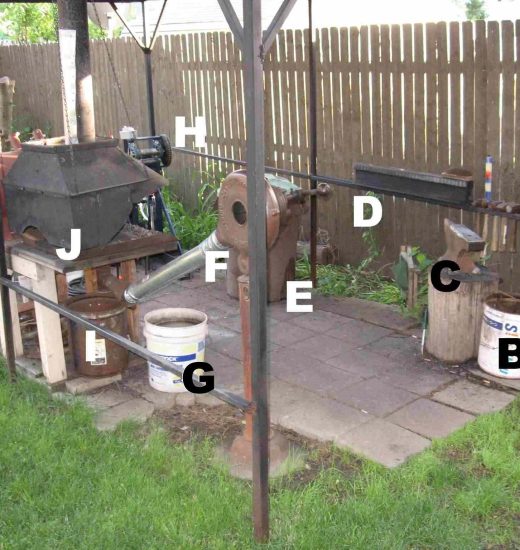

I have had E-mails asking about working with a forge, so here is my old shop, and how I used it. Click the pictures to get a full screen photo.

OUR PRODUCTS

OUR GALLERY

Our Books

The front cover for Knifemaking 2.0

I would like to present my second book

“Knifemaking 2.0” .

The book is in 6×9 inch softbound format with 221 pages with many black and white illustrations and photos. Regular retail price is Soft cover is 28.99 plus $10.00 shipping/handling to the US for a total of $36.99. Hard cover is 46.99 plus $10.00 shipping/handling to the US for a total of $56.99 delivered in the USA.

For purchase use paypal

slsells AT fenrisforge.com

Foreign orders please Email me for information.

The front cover for Introduction to Knifemaking.

I would like to present my first book “Introduction to knifemaking” .

The book is in 6×9 inch softbound format with 212 pages and 102 black and white illustrations. Regular retail price is Soft cover is 29.99 plus $10.00 shipping/handling to the US for a total of $39.99. Hard cover is 47.99 plus $10.00 shipping/handling to the US for a total of $57.99 delivered in the USA.

For purchase use paypal

slsells AT fenrisforge.com Foreign orders please Email me for information.